Reducing Burden of Inspection Work inside Manholes with Remote Monitoring Systems Using Underground Power Transmission Lines

Manhole Monitoring System Using Existing Power Cables as Transmission Line

Tetsuo Goto,

Assistant Manager, Power Cable Projects Division

The maintenance of underground power transmission lines is performed manually by specialized engineers entering manholes. While underground power transmission networks have been spreading in recent years, aging power transmission lines and a future shortage of maintenance engineers have become apparent. As a result, there has been a strong need realizing a remote monitoring system using the latest digital technology. However, even if sensors and other monitoring devices are installed underground, information from the sensors was not be communicated due to the lack of an appropriate communication environment.

Focusing on the fact that underground power transmission lines themselves can be used for communication, we have developed a remote monitoring system that communicates information necessary for maintenance from inside manholes, in cooperation with TEPCO Power Grid, Inc.

Difficulties in inspecting underground power transmission lines

In areas where it is difficult to build new transmission towers due to the issues of land security and landscape, power cables are laid underground. For this reason, maintenance engineers regularly enter manholes to inspect cables and incidental facilities. However, inspection work in manholes has presented many challenges. For example, the work is inefficient because it is conducted only at night when there is little traffic, there is a danger of rainwater or gas accumulating in the manholes, and the power lines are aging. In order to reduce the burden of inspection work in manholes, the development of a system to remotely monitor the inside of manholes has been considered. However, even if monitoring units are installed inside manholes, there was no means to stably communicate the information obtained with the devices. This was because radio waves for wireless communication are blocked by metal manhole covers, and installing new communication lines, such as optical fibers, was physically and economically unrealistic.

Using high-voltage power cables for both data communication and power supply

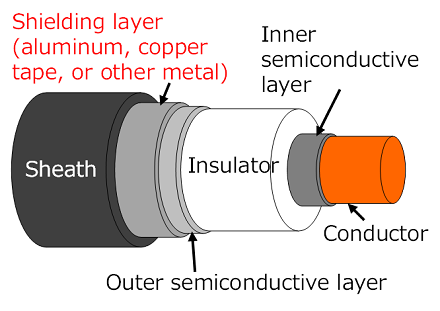

Therefore, we considered using power line communication (PLC) technology, which uses power cables themselves for communication. If this technology could be applied to existing power transmission cables, there would be no need to install new communication cables. However, PLC is a technology normally used for low-voltage power cables of about 600 V, and its application to 500 kV high-voltage underground transmission lines, which we handle, was unprecedented. As a PLC transmission medium, we looked at using the metal shielding layer (Fig. 1) provided for improving the characteristics and safety of high-voltage cables. After overcoming various challenges, we first conducted an in-house simulation experiment of PLC using the metal shielding layer and confirmed that there was no performance problems. Then, we conducted tests using an actual power transmission line of TEPCO Power Grid and obtained results that supported the practicality and reliability of the technology. We felt a great sense of accomplishment.

In addition, the metal shielding layer has the ground wire drawn out at the end of the cable and the intermediate connection in manholes, which provides the significant advantage of enabling contactless information communication through inductive coupling using a device called a current transformer (CT). Electric power for monitoring units, such as sensors and cameras, could also be extracted from power cables through electromagnetic induction using another CT.

Fig. 1. Structure of power cable

An advanced sensor network system built inside manholes

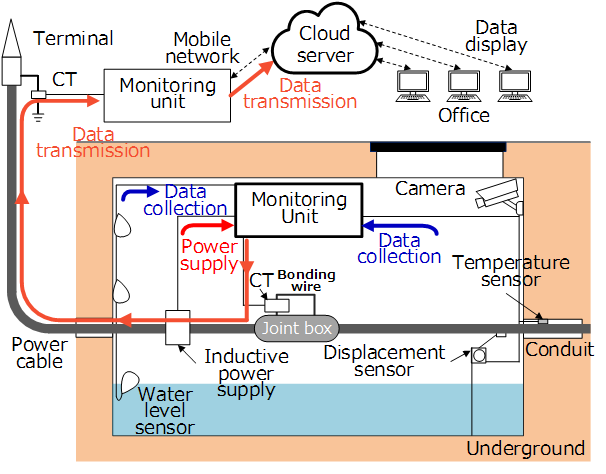

In order to prevent water from penetrating inside a monitoring system even when it is submerged in a manhole, we improved an existing housing that has a proven track record of withstanding a water depth of 10 m at the site of optical cable connection and successfully ensured the waterproofness of the system at a low cost. As a result, it became possible to install sensors for detecting the temperature and other conditions of cables and water level changes, and cameras for real-time monitoring inside manholes. Thus, we completed an advanced sensor network system that collects and communicates the information necessary to monitor the status of underground power transmission lines. The digital information collected with the sensor network system is communicated to a terminal on the ground through PLC, sent to a cloud server via mobile networks, and stored. Stored data can be analyzed on the cloud server and made use of for safe and efficient maintenance and management of underground power transmission lines (Fig. 2). This monitoring system enables maintenance according to the degree of deterioration of cables, thereby reducing unnecessary maintenance costs. In addition, constant monitoring enables the early detection of signs of failures and defects, which leads to the prevention of accidents.

Fig. 2. Configuration of maintenance monitoring system for transmission line in manhole

Aiming for more advanced and efficient remote monitoring

Currently, this PLC-based monitoring system is operating at two sites of actual power transmission lines. Although we have successfully established a means of communication through this research and development, in order to perform detailed deterioration diagnosis of equipment and use power transmission lines more effectively, it is important to further improve data acquisition and develop more sophisticated apps. We are already working jointly with customers to conduct demonstrations assuming application to actual power transmission lines in order to realize a more advanced and efficient remote management system using new measuring equipment and an AI-based data analysis technology. We will continue to provide technological solutions to issues related to the maintenance and operation of power transmission lines in order to ensure a stable supply of electricity.

SUMITOMO ELECTRIC TECHNICAL REVIEW

A journal of technical papers explaining the Sumitomo Electric’s technologies. Technical papers are available in PDF format.

Learn more